Bill of Materials (BOM)

Simplify and refine your BOM processes.

An ERP Built for BOM Management

Optimizes cost management and inventory control for every production workflow through real-time data and analytics.

- Component Listing

- Assembly Instructions

- Cost Estimation

- Revision Control

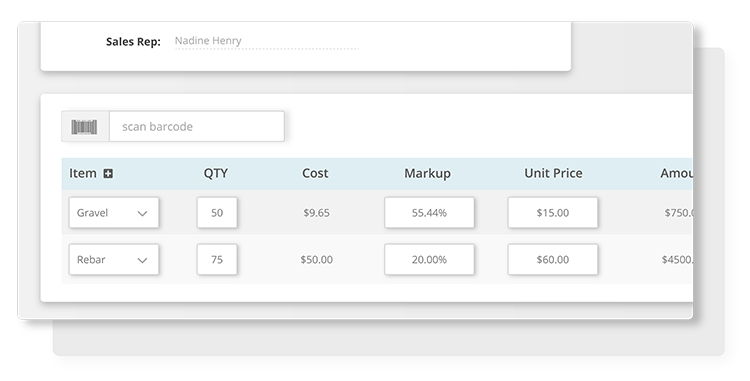

Component Listing

Dive deep into the specifics of your manufacturing needs with a detailed component listing. Striven enables you to catalog every item down to the smallest part, ensuring nothing gets overlooked.

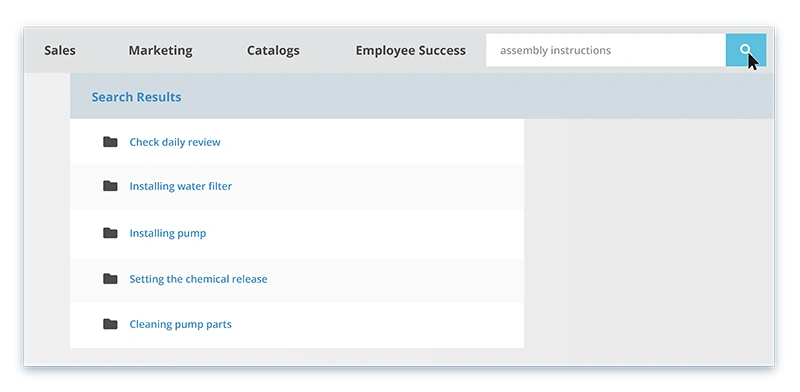

Assembly Instructions

Transform complexity into clarity. Striven’s assembly instructions feature allows you to attach detailed guidelines, ensuring each product is built consistently and to your exact standards.

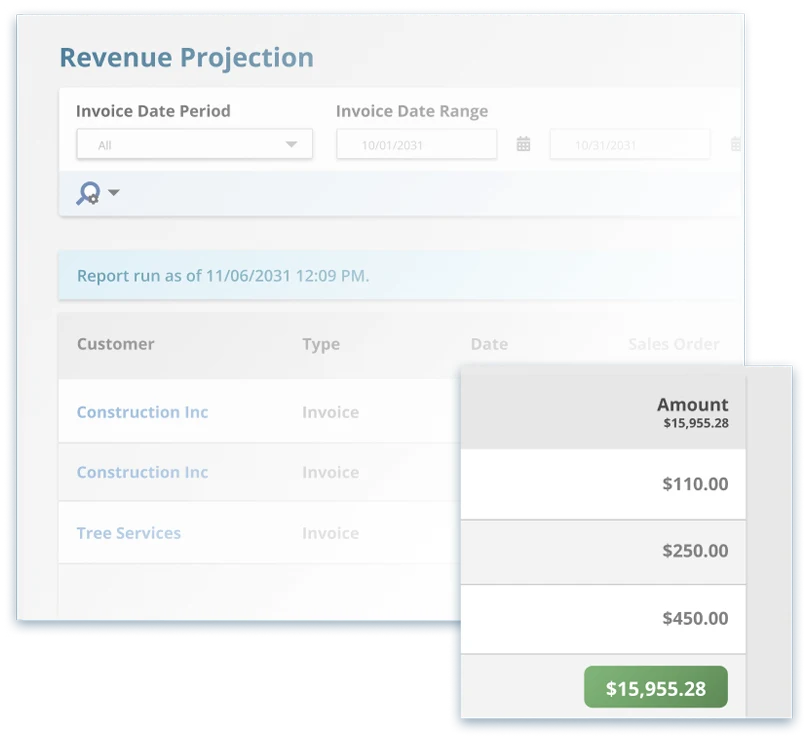

Cost Estimation

Make informed financial decisions with Striven’s cost estimation tools. By analyzing the direct and indirect costs of each component, our software provides you with a comprehensive overview, helping you to optimize pricing and margins.

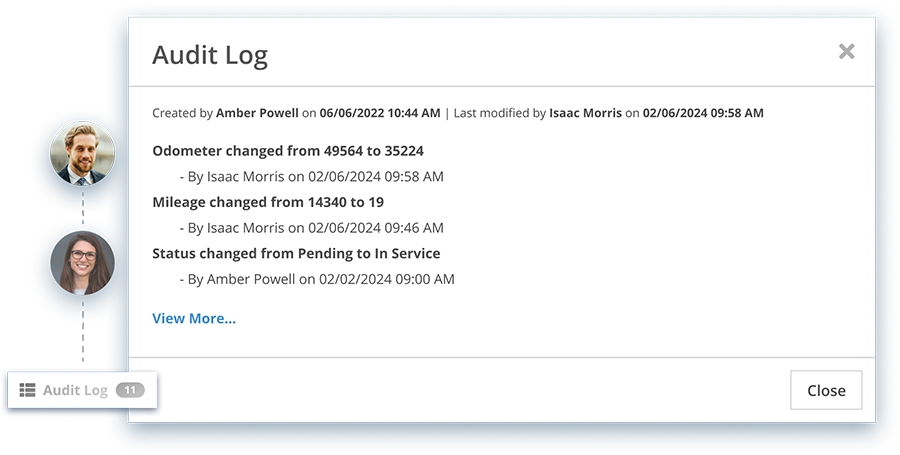

Revision Control

Keep your BOMs up to date with our robust revision control feature. Track changes, update components, and ensure that your team always works from the latest version, minimizing errors and waste.

“Striven really helps us keep our accurate. We all LOVE it!”

—Clyde G., G2 Review

Ready to try it? Start here.

Frequently Asked Questions

-

How does Striven ensure the accuracy of its BOM listings?

+

Striven employs a detailed verification process, allowing users to meticulously catalog every component and verify their specifications, ensuring unmatched accuracy in production planning.

-

Can I attach files or documents to assembly instructions in Striven?

+

Absolutely. Striven allows for the attachment of detailed guidelines and files to ensure that assembly processes are clearly communicated and standards are consistently met.

-

How does Striven help with cost management in BOM?

+

Our software provides detailed insights into both direct and indirect costs of components, enabling better pricing strategies and margin optimization.

-

What makes Striven’s revision control feature stand out?

+

Striven’s revision control provides a comprehensive history of changes, updates, and modifications, ensuring all team members access the most current version of BOMs.

-

Is it possible to customize BOMs for specific products or projects?

+

Yes, Striven allows for customizable BOMs that can be tailored to meet the unique needs of any product or project, enhancing flexibility and efficiency.

-

How does Striven’s BOM feature integrate with other ERP modules?

+

Striven’s BOM features are fully integrated with inventory, accounting, CRM, and project management modules, providing a seamless operational workflow.

-

Can Striven handle BOMs for complex products with multiple components and assemblies?

+

Definitely. Our system is designed to manage complex BOMs, no matter the number of components or sub-assemblies, ensuring detailed tracking and management.

-

What support does Striven offer for setting up and optimizing BOMs?

+

Striven provides comprehensive support resources, including guides, video tutorials, and customer support, to help users maximize the benefits of BOM features.

Striven's Got You Covered

Whatever your business, Striven is here for you, making your supply chain management a breeze.